Super Finishing for Racer and Engineer Gives Five Percent Performance Boost, Less Friction and More Reliability

Super Finishing for Racer and Engineer Gives Five Percent Performance Boost, Less Friction and More Reliability

Fintek

Unit 1

Dean Court

Harvard Road

Bury

BL9 0GF

Advanced OTEC Surface Finishing Machines at MACH 2026 - Fintek Stand 18-12

Fintek to show advanced post-processing and surface finishing technologies at MACH 2026 on stand 18-12. Aimed at manufacturers with demanding production and quality neds, they will highlight machines designed to deliver speed, capacity and precision. Along with Orbitool, an innovative device to easily deburr cross-drilled holes.

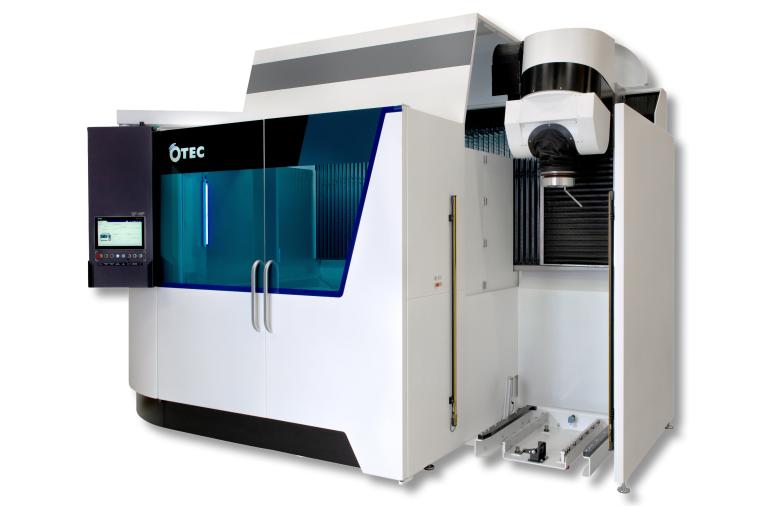

At the heart of the stand will be Fintek’s range of OTEC Präzisionsfinish machines, for which the company is the UK agent. OTEC is globally recognised for its disc (CF), drag (DF), stream (SF) and electro-finishing (EF) technologies. All engineered to achieve consistent, repeatable, precise, high-quality surface finishes. Across a range of metals and component geometries, from simple to complex.

A key focus at MACH 2026 will be Fintek’s capability to support finishing of larger components. SF processing is now available for parts up to 900mm in length and 900mm in diameter. This reflects growing demand from sectors such as aerospace, motorsport and tooling. Component size is increasing but tolerances remain tight.

Superfinishing and mass finishing will also feature. OTEC stream finishing meets the needs of manufacturers for high throughput with precision. Surface roughness values are achievable down to Ra 0.01µm, often in minutes. These systems enable manufacturers to meet stringent specifications while supporting efficient, scalable production.

OTEC SF machines can include their proprietary Pulsfinish technology. Alternating the direction of rotating heads, Pulsfinish generates intense relative motion between the finishing media and workpiece. Rapid acceleration and deceleration increase finishing forces. This delivers faster cycle times and superior surface quality. It also preserves critical workpiece geometry.

Automation will be another major theme on the Fintek stand. Options range from chain-feed loading systems through to robotised loading and unloading. This enables seamless integration into automated production lines. These options help to reduce manual handling, improve consistency and support lights-out manufacturing.

All OTEC machines are Industry 4.0 ready. Offering connectivity and data transparency as standard. For manufacturers seeking deeper digital integration, an advanced package is available. This includes an industrial PC for enhanced machine monitoring, process optimisation and remote maintenance. It allows users to maximise uptime and process control.

Fintek is also the UK agent for the J W Done patented Orbitool. A technology for the in-process deburring of cross-drilled holes. Traditional off-line processes interrupt and slow down modern manufacturing flows. Fintek will show how Orbitool will save manufacturers time and cost when deburring cross-drilled holes.

Besides machine sales, Fintek provides a full subcontract surface finishing service. The company processes components for manufacturers in aerospace, motorsport, medical devices, implants and more. Subcon also allows customers to prove and validate a finishing process before committing to the purchase of an OTEC machine.

Fintek provides full support in the UK and operates to ISO9001 and AS9100 standards. Underscoring its commitment to quality and reliability.

Fintek are on stand 18-12 at MACH 2026. Registration machexhibition.com.

More Information

Jamie Phillips, General Manager, Tel. +44 (0)1706 825819

Fintek, Unit 1 Dean Court, Harvard Road, Bury, Lancashire, BL9 0GF

Email: jamie@fintek.co.uk Web: www.fintek.co.uk

Browse Articles

Next >

Fintek News Archive

Unit 1 Dean Court

Harvard Road

Bury

Lancashire BL9 0GF