Nadcap Gold Merit Accreditation for Wallwork Heat Treatment

Nadcap Gold Merit Accreditation for Wallwork Heat Treatment

Wallwork Group

Lord Street

Bury

Greater Manchester

BL9 0RE

United Kingdom

Smooth Braking for Sheffield Motorsport Students

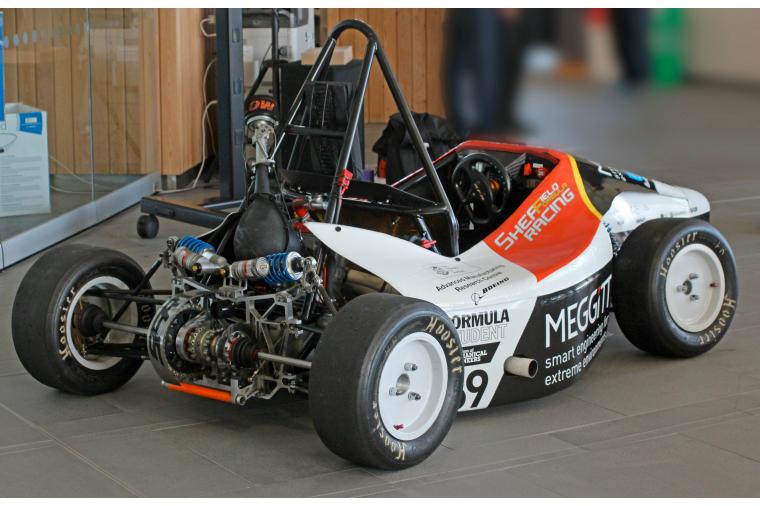

Formula Student is an international competition to build a racing car from scratch, attracting over 100 new engineering undergraduate teams to Silverstone every year. The 2015 team from The University of Sheffield Mechanical Engineering Department overcame myriad technical challenges in translating their design from a computer model to a race-ready car. A particularly sticky problem with brake components was solved in collaboration with hard coating specialist Wallwork Cambridge.

Team Principal, Thomas Bloomfield explained, “Design of components requires extensive and complex CAD work to ensure all the parts will fit together, but the most difficult task is often the parts manufacture. Using additive manufacturing (3D Printing) gives us high flexibility. An ability to make extremely accurate and lightweight components ensures the car has a good power to weight ratio for race advantage.”

Final year student Nathaniel Wellicome led the chassis and vehicle dynamics team who selected titanium as the material for callipers and other key brake components. He explained, “Strong, fatigue resistant and most of all light in weight, titanium has many advantages in this situation but also one major drawback because of its very poor coefficient of friction. Being a relatively soft material, compared to say steel, it can bind in metal-to-metal contact under load. We therefore approached Wallwork for their advice on hard coatings, given their particular aerospace and motorsport experience.”

Dr Jonathan Housden of Wallwork takes up the story, “The parts were manufactured by the Sheffield students using an additive process where metal powder is fused by electron beam melting (EBM) to create the complex component shapes. Machining of the mating surfaces had been undertaken to overcome the surface roughness that is typical of EBM and provide a smooth substrate to apply the coating. Simply applying a hard coating to this machined surface would be insufficient since the titanium substrate alone is too soft and the coating would fail, so we applied a duplex coating, Nitron-O. Using this process we first nitride the surface to produce a hard layer to support the subsequent titanium nitride coating. Nitron-O enables titanium alloy to be used in high-load sliding wear situations where it could not otherwise be used. It provides a hard-wearing and low friction surface to prolong service life.”

Components have been returned to Sheffield for final assembly and trials before the race event. International teams will gather at Silverstone for the race and technical judging between July 9 and 12 after which the students will disperse to follow careers in industry or further study.

Thomas Bloomfield concluded, “Students carrying out this challenge commit to a time demanding task undertaken alongside their degrees. This means they develop fantastic time management skills and learn how to deal with realistic high pressure fast-paced environments. This makes them very employable and is why some companies, like Wallwork, are happy to sponsor the team by sharing their expertise. For Wallwork, Dr Housden added, “Engineering is a dynamic profession and projects like this help us engage with the next generation of engineers, a collaboration that is mutually beneficial.”

Anyone wanting to follow the Sheffield student motor engineers' story can do so on their You Tube channel https://m.youtube.com/watch?v=1wg7llyBHhk.

More Information

Simeon Collins, Sales Director, Tel. +44 (0)161 797 9111 Fax. +44 (0)161 763 1861

E-mail: simeon.collins@wallworkht.com Web: www.wallworkht.com

Wallwork Heat Treatment Ltd, Lord Street, Bury, Greater Manchester, BL9 0RE, UK

Press release issued: June 25, 2015

Browse Articles

< Previous |

Next >

Unit 1 Dean Court

Harvard Road

Bury

Lancashire BL9 0GF