Metal Component Post Processing & Surface Finishing – MACH: Fintek Stand 19-16

Metal Component Post Processing & Surface Finishing – MACH: Fintek Stand 19-16

Fintek

Holcombe Brook

Bury

BL0 9SA

United Kingdom

GE Certification Adds to Aerospace Surface Finishing Ambitions of Fintek

GE certification for mass surface finishing has been gained by Fintek. Adding to their existing AS9100 and AS9001, the new certificate is an important milestone for the company as they continue to expand their subcontract surface finishing services in the aerospace sector.

Fintek is engaged in pioneering work with several aerospace component manufacturers, working closely with them to eliminate production bottlenecks where hand and traditional finishing methods are not able to achieve higher quality surface finishing requirements in shorter times.

Of particular concern for many aerospace parts manufacturers is unseen damage caused by manual deburring using small powered hand tools. These can sometimes cause accidental nicks that can compromise fatigue requirements, possibly with catastrophic consequences. Another hand finishing issue is missed burrs that are subsequently peened over. Again these can become sources of component failure.

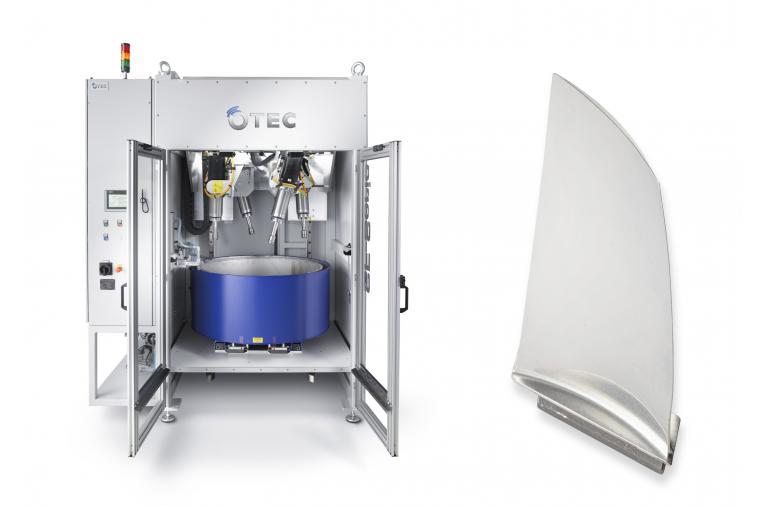

Key in addressing these issues has been the introduction of highly controllable stream finishing systems by OTEC Präzisionsfinish GmbH. Fintek, who represent OTEC in the UK, has been able to develop special processes to dramatically improve the efficiency and, importantly, the quality of the surface finishing for aerospace manufacturers. Typical components benefiting from superior and more consistent surface finishing includes turbine blades, extremely thin parts, gear wheels, fasteners and even cutting tools.

To accommodate additional stream finishing units and meet demand for these processes, Fintek is planning to extend their existing facility. “These are exciting times as much of the research and development work we have undertaken with F1 teams, the pinnacle of motorsport, is proving to be adaptable to aerospace and we can offer manufacturers mass finishing options to boost productivity and quality where previously they did not exist. This GE certification is another step forward for us,” Jonathan Dean, managing director, concluded.

More Information

Jonathan Dean, Managing Director Tel. +44 (0)1706 82 5819

Fintek, Halter Inn Works, Holcombe Brook, Bury, Lancashire, BL0 9SA

Email: info@fintek.co.uk Web: www.fintek.co.uk

Release issued: June 03, 2019

Browse Articles

< Previous |

Next >

Fintek News Archive

Halter Inn Works

Holcombe Brook

Bury

Lancashire

BL0 9SA